20

2022

-

10

Take you to understand the internal structure principle of steel wire seal

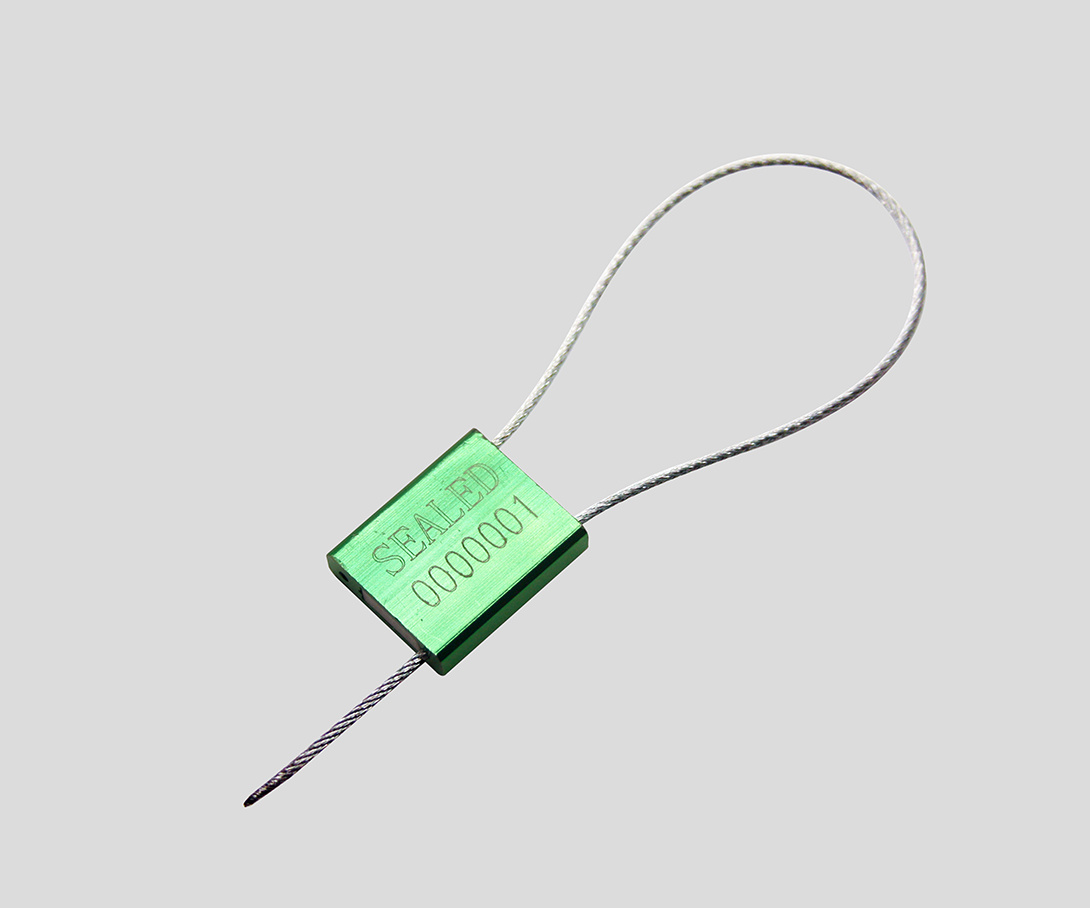

Common steel wire seals in addition to the appearance of the difference, the principle is similar, generally divided into tight wire seals and both ends of the plug-in wire seals, which are commonly used to tighten the wire seal.

In fact, the internal principle of tightening the steel wire seal is very simple. The inside of the lock body is fixedly connected to the lock body through one end of the lock belt, and the other end of the lock belt is connected to the lock head. The lock body is provided with a counterbore through which the lock head can pass. The lock body has two inclined holes communicating with the counterbore. Each inclined hole is equipped with a spring. The intersection of each inclined hole and the counterbore is equipped with a steel ball. The steel ball is supported by the corresponding spring. The lock head is provided with two grooves, which are respectively matched with the two steel balls. When sealing, when the lock belt passes through the sealing part of the package, insert the lock head into the through the through the through the lock body, the two steel balls in the lock body respectively enter the two grooves on the lock head, and the two steel balls are respectively pressed into the two grooves on the lock head under the action of the corresponding springs, and the lock head is locked. The sealing can be completed. Through the cooperation of two steel balls and two grooves on the lock head, the lock head can be locked more firmly.

Steel wire seal conditions are widely used in various industries, such as freight containers, trucks, trucks and other goods, steel wire seal in the structure and material are different from ordinary lead seal, so that criminals can not re-engraved steel wire seal, to prevent the occurrence of imitation or embezzlement, can bring huge economic benefits to public utility companies.

The steel wire seal condition is a disposable product. If the steel wire seal is to be untied, cut with wire cutters, scissors, etc., the cut steel wire seal cannot be used. If the steel wire seal can be untied intact, it means that the product is unqualified and is a waste product. However, in the production process, the quality inspector will check one by one. The steel wire seal condition with slipping phenomenon will be actively destroyed. What conditions should the steel wire seal meet during use? Let's answer it for everyone below.

The steel wire seal has been sealed on six sides and can be used on freight seals such as containers, truck doors and oil tankers. Once sealed, it cannot be opened and can only be cut open. The lead seal has a certain size. Generally, the diameter of the steel wire is 1.8mm, the length of the exposed steel wire is 240mm, and the total length is 265mm. However, the size of the sealed article must not exceed this size, otherwise it is not easy to be blocked. Therefore, the steel wire seal; the steel wire seal is a combination of steel wire and lock body. It has good anti-theft and anti-counterfeiting effects. It can be used in freight transportation, home decoration and other fields. It is small in style, convenient to operate and low in price. However, the steel wire seal condition is a disposable consumable. If you want to open it after use, you must use sharp tools such as pliers or scissors to cut it off. Some steel wire lead seals have shortcomings because some manufacturers do not meet the standards, cause the product has slippery silk or too loose phenomenon, easy to be untied, such products can not play anti-theft, anti-counterfeiting effect.

Steel wire seal

Previous page

recommend News