09

2022

-

11

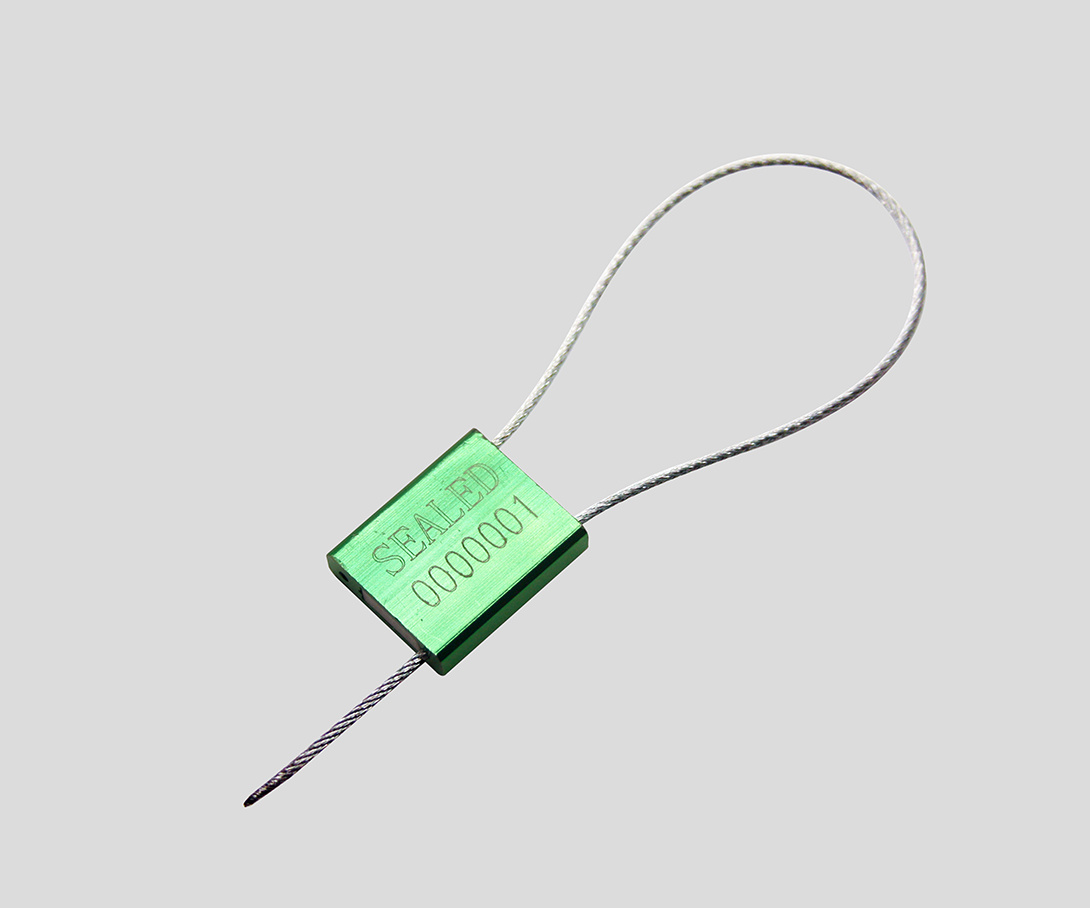

Advantages of steel wire seals for construction and major industries

Plastic steel wire seals are commonly used in electronic factories, warehousing, PetroChina, banking, finance, enterprise product inspection, packaging barrels, energy metering, anti-theft plugging, department stores, logistics, radio and television express, express delivery, shipping companies, buildings. This application is now very mature. What are the reasons for the preference of steel wire seals in various industries?

1. The steel wire seal has the characteristics of high strength, good adhesion and complete combination of putty. Convenient construction, reduce labor intensity, speed up construction, reduce construction costs. The appearance is straight, and greatly improves the impact on the wall, protects the wall from damage, and effectively avoids the trouble of corner damage and repeated maintenance.

2. Flexible, convenient construction, beautiful arc.

3. The long-standing quality problems in construction, such as the sun corners are not straight and beautiful, and the corners are easily damaged. In the corner of the external wall insulation, the construction speed is slow, the impact resistance is poor, after a long time of weathering and water seepage, the wall is cracked.

4. It can be used to make complex shapes, easier to form than metal, low energy consumption, low cost, corrosion resistance and light weight.

5. Plastic is soft, easy to fold, good light transmittance, low price and low production cost. The raw materials are also very extensive, non-perishable, flexible, small footprint, and wide application fields.

6. High antistatic, not easy to age, good electrical insulation.

Plastic steel wire seal can solve all the above quality problems, the problem that the project is difficult to cross the wall, to ensure that the insulation layer does not crack, the glass fiber grid cloth has high bonding strength, and the acid-base plastic strip. However, the use of this product can also improve the level of earthquake resistance and reduce the construction difficulty of plastic sealed doors and earthquake disaster corners. It is a specially designed new building material. Unique climate, corrosion resistance, anti-aging and other characteristics. Plastic packaging known for its strength and toughness can be assured, rather than traditional building materials such as steel, wood, and aluminum.

At present, in the competitive market environment, in order to improve the competitiveness of products, manufacturers have invested a lot of energy in product differentiation, in order to maintain a good residual rate and low cost. This difference is mainly achieved through design, visual appearance, or the need for smaller and more mature systems as new functions are developed. The economic rationalization of components is another important trend in the industry, for example in the automotive, equipment, electronics and medical fields, because it increases reliability and reduces total costs.

Although the steel wire seal is covered with a layer of ABS plastic, the cost is only slightly higher than that of ordinary steel wire seal, so it is very popular. With the development of the lead sealing industry, people's pursuit of lead sealing products is not only limited to quality and price, but also has a higher pursuit in terms of beauty.

For these reasons, plastic wire seals and other traditional materials have become one of the main strategies for many market products.

Steel wire seal

recommend News